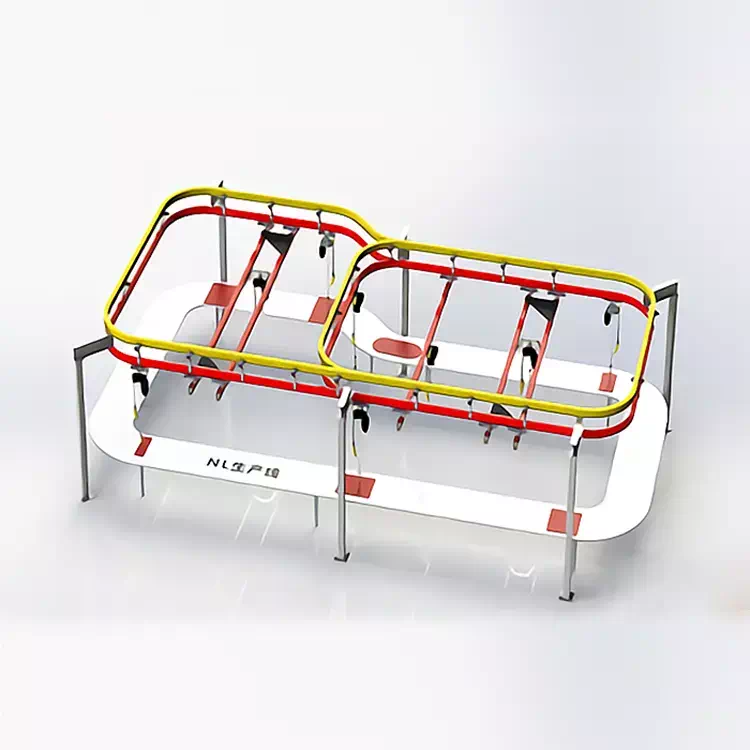

Flexible Combined Crane

- 0.1t

- 0.5t

- 1t

- 2t

- 3t

- 5t

- A3

-

Lifting hook

Lifting hook

- Product Overview

- Application Scenario

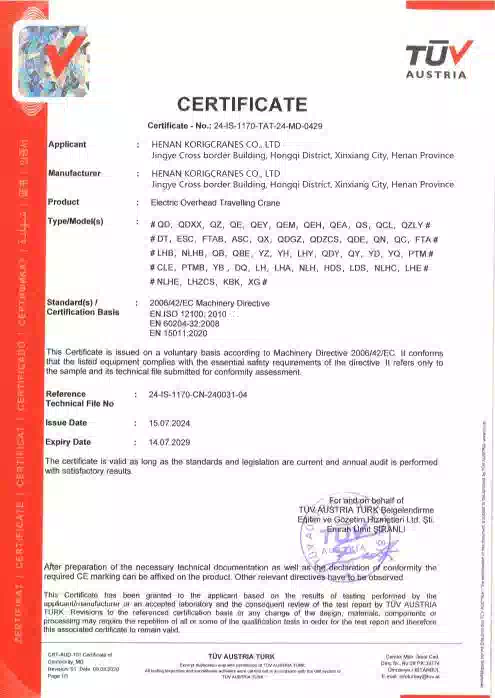

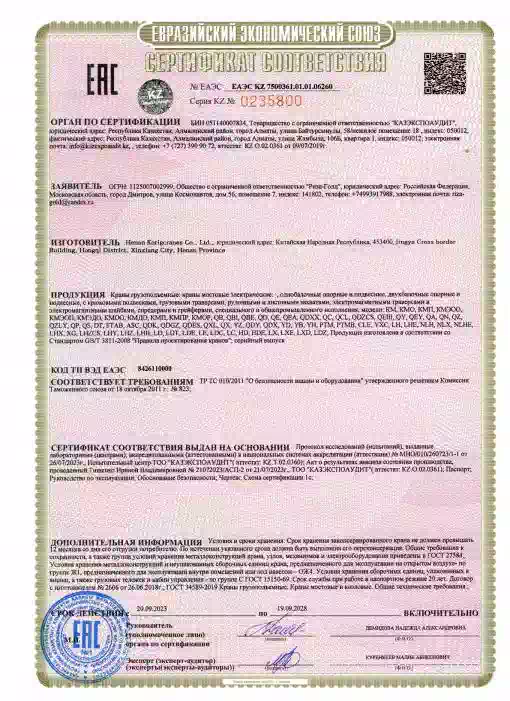

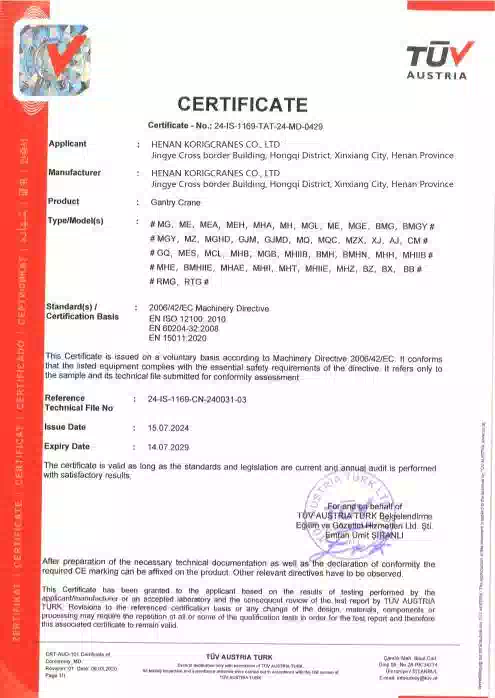

- Certificate

Flexible Light Combined Crane is constituted by the track, electric chain hoist and installation components. This crane can be a very simple equipment with 2 straight rails, also can be very complex suspended monorail system. Flexible light crane has simple operation of manual operation also has complex operation such as automatic system operated by compute integrated control.

Flexible operation of this crane makes it more convenient for different handling of materials. It can realize reinstallation and reconstruction by regrouping the components or adding some other components.