Magnet Double Girder Overehad Crane

- 1t

- 3t

- 5t

- 10t

- 20t

- 50t

- A5

- A6

- A7

- A8

-

Magnetic chuck

Magnetic chuck

- Product Overview

- Application Scenario

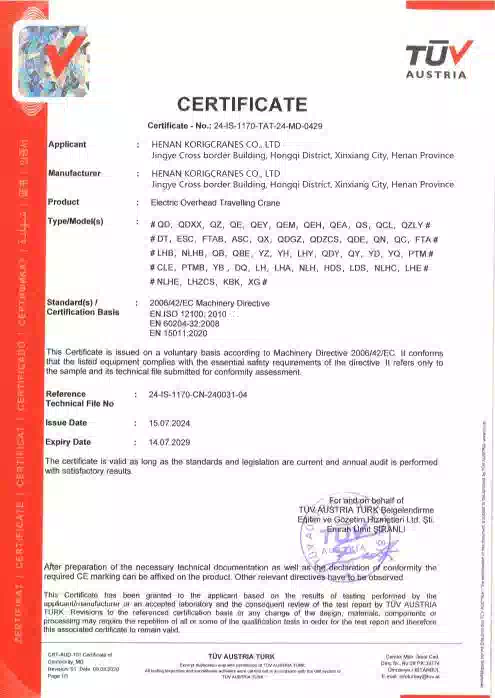

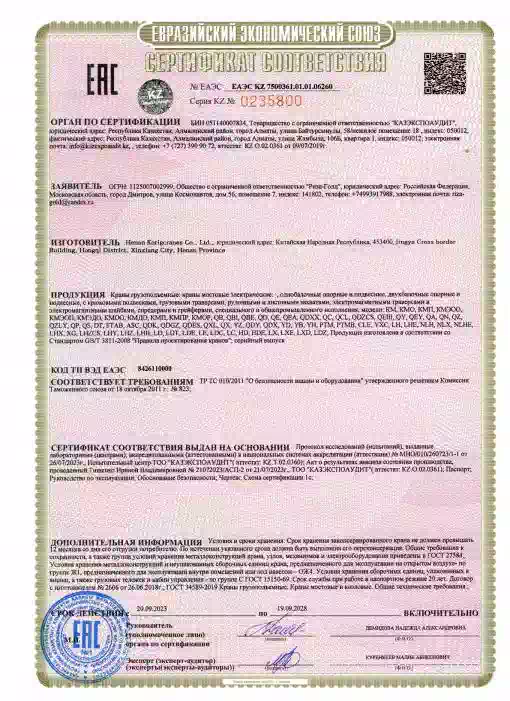

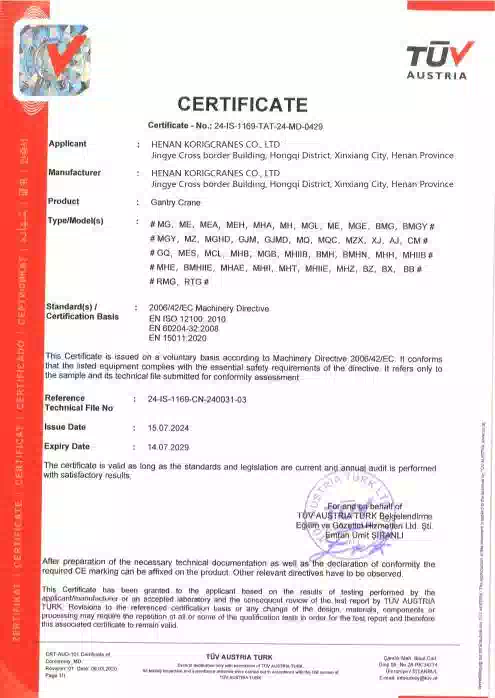

- Certificate

Overhead crane with electromagnetic beam is a specialized crane for lifting and moving steel products, steel plates and steel pipes. This crane is constituted by girder, traveling mechanisms, lifting trolley, electric parts and electromagnet spreader. The electromagnetic suction force of this overhead crane can last 10 minutes after power off. And the shape of electromagnet spreader could be customized bases on the shape of materials to be lifted. There are 2 types of electromagnet spreader: electromagnetic chuck and electromagnetic beam. And electromagnetic beam can also be 2 kinds: non-rotating beam (vertical or parallel to main girder) and rotating beam (Upper beam or hanging beam).

There are 2 types of electromagnet spreader: electromagnetic chuck and electromagnetic beam. And electromagnetic beam can also be 2 kinds: non-rotating beam (vertical or parallel to main girder) and rotating beam (Upper beam or hanging beam).

Features of Double beams overhead bridge traveling magnetic crane:

1. Overhead traveling on the steel structure, normally in workshop, heavy working duty from A5-A8.

2. With magnetic/magnet plate under the crane as the lifting tool, to lift steel scrap, steel material etc.

3. Soft start, 3-5 speeds to operate, very stable to lift and running.

4. Six direction action, to make sure the enough wide working ared.

5.Full safety system as follows:

* Weight overload protection

* Emergency stop system

* Over current protection, short-circuit protection

* Phase sequence proetction

* Zero position proetection

* Voltage loss protection

* Limit switch and stopper for crane long traveling and cross traveling

* Lifting overhigh and overlow limit switch