Home / Products & Cases / Details

Precast Beam Lifting Gantry Crane

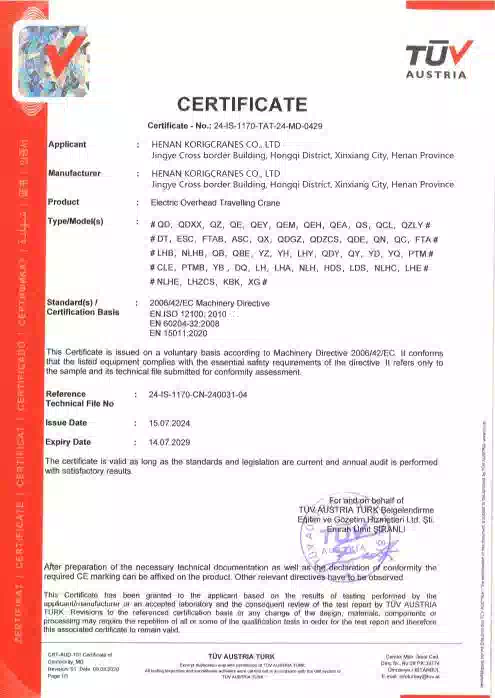

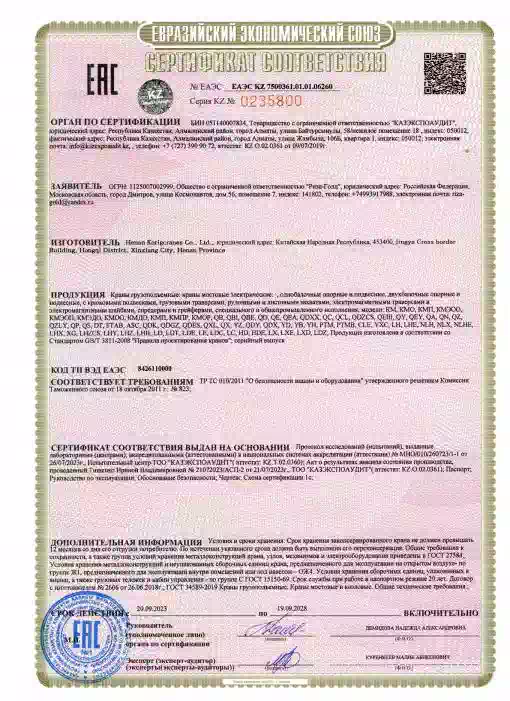

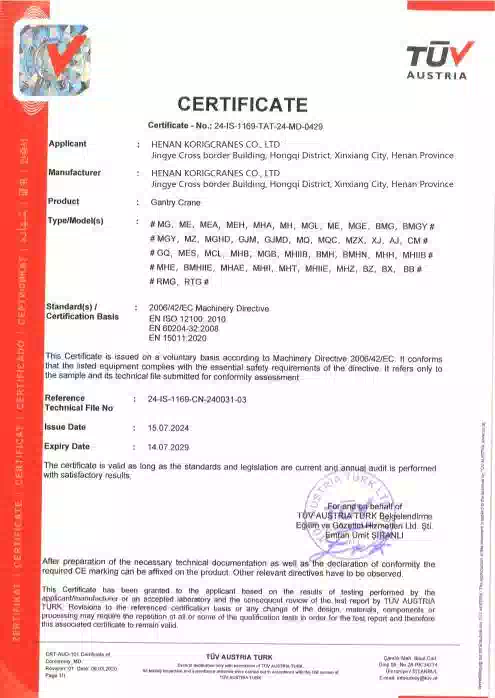

Authentication mark:

The following options can be selected:

Lifting capacity:

- 450t

- 900t

Lifting height:

Span:

Voltage/Hertz:

Job level:

- A5

Sling available:

-

Lifting hook

Lifting hook

Apply:

Precast beam lifting gantry crane is mainly used to hang the prefabricated beams from the beam making site to beam storage site and to trucks.

- Product Overview

- Application Scenario

- Certificate

The beam lifting gantry crane is a highly specialized type of crane, meticulously designed to meet the unique demands of bridge construction projects. Its robust construction and advanced engineering make it an indispensable asset in this field.

This gantry crane offers remarkable flexibility in its operation. It has the capacity to work independently, with a single unit capable of handling loads up to 900t. This is especially useful when dealing with large - scale precast beams that require a substantial amount of lifting force. In other scenarios, two cranes, each with a capacity of 450t (450t + 450t), can be deployed to work in tandem. This collaborative approach is highly effective for lifting precast beams of a size or weight that is more efficiently managed by the combined effort of two units. The synchronization of the two cranes is carefully engineered, ensuring seamless coordination during the lifting process.

In the context of bridge construction, one of its primary functions is to transfer prefabricated beams. It plays a crucial role in the transition of these beams from the beam making site to the beam storage site. At the beam making site, where precast beams are fabricated with precision, the beam lifting gantry crane carefully hoists the beams using its specially designed lifting attachments. These attachments are engineered to firmly grip the beams without causing any damage, ensuring the integrity of the precast elements. The crane then smoothly transports the beams along the tracks or designated path to the beam storage site, where they are temporarily stored until needed for further installation.